|

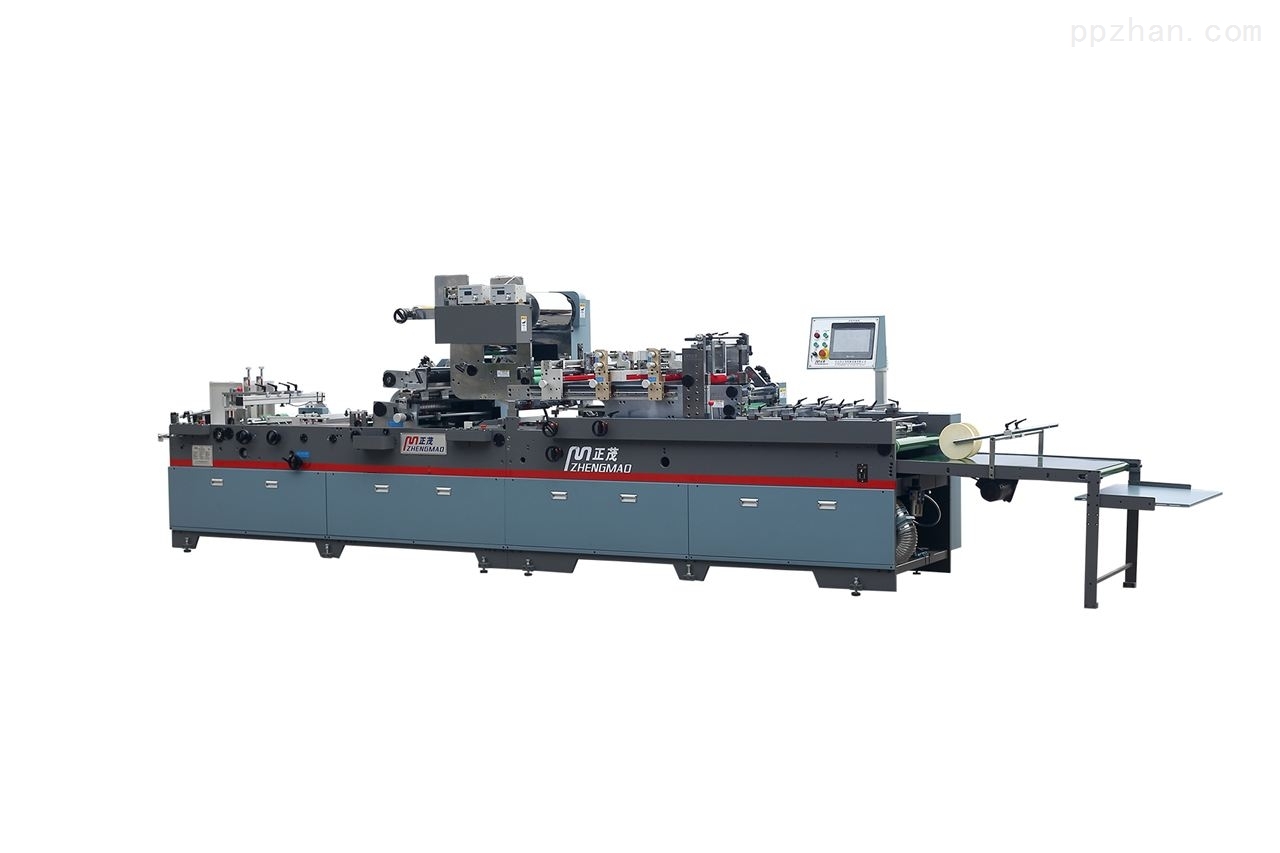

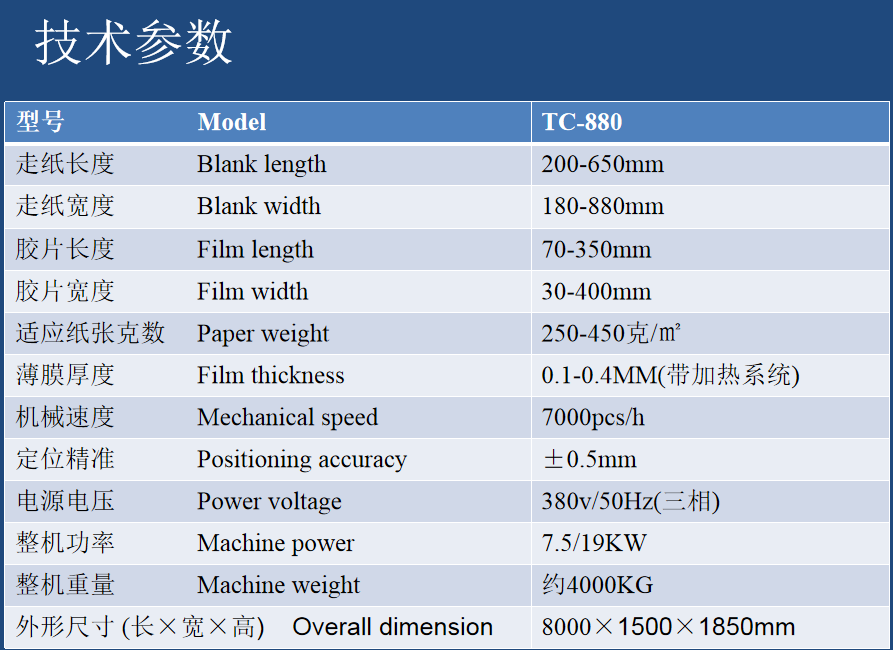

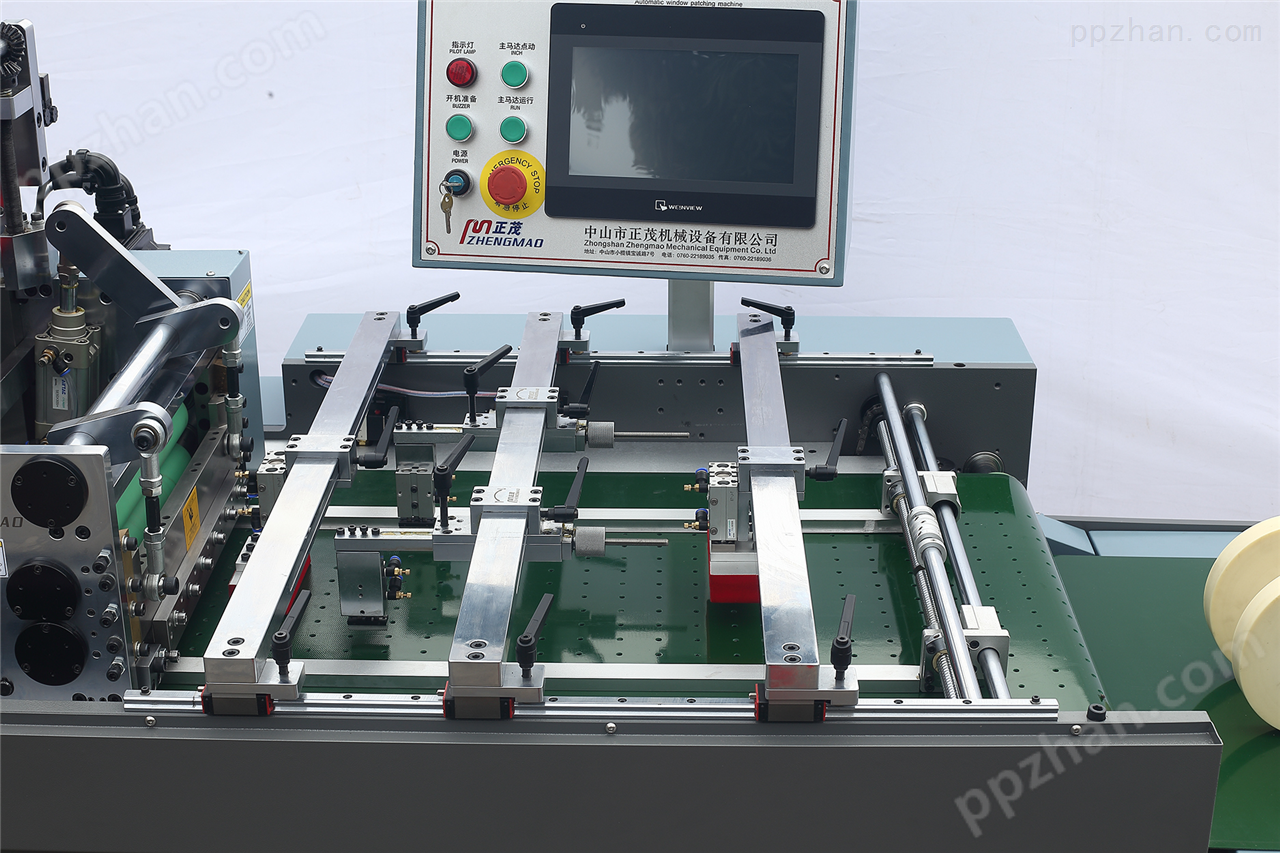

TC-880 Window Patching Machine

The TC-880 Window Patching Machine suitable for all type windows. Its functions including patching window, press line, cut corner, embossing logo, punch hole and etc. High efficiency, high precision. |

1.

TC-880 multifunction window patching machine suitable for all type windows. It has a number of functions including patching window, press line, cut corner, embossing logo, punch hole and so on, also has the characteristics of high precision, stability and high performance. User friendly operation, make your work easier and better. The company has always been committed to full auto film machine R & D, manufacturing. In the long run printing factory work experience, with advanced design and production experience.

2.

3. The Machine is composed of four units: feeding unit, gluing unit, window patching unit, delivery unit.

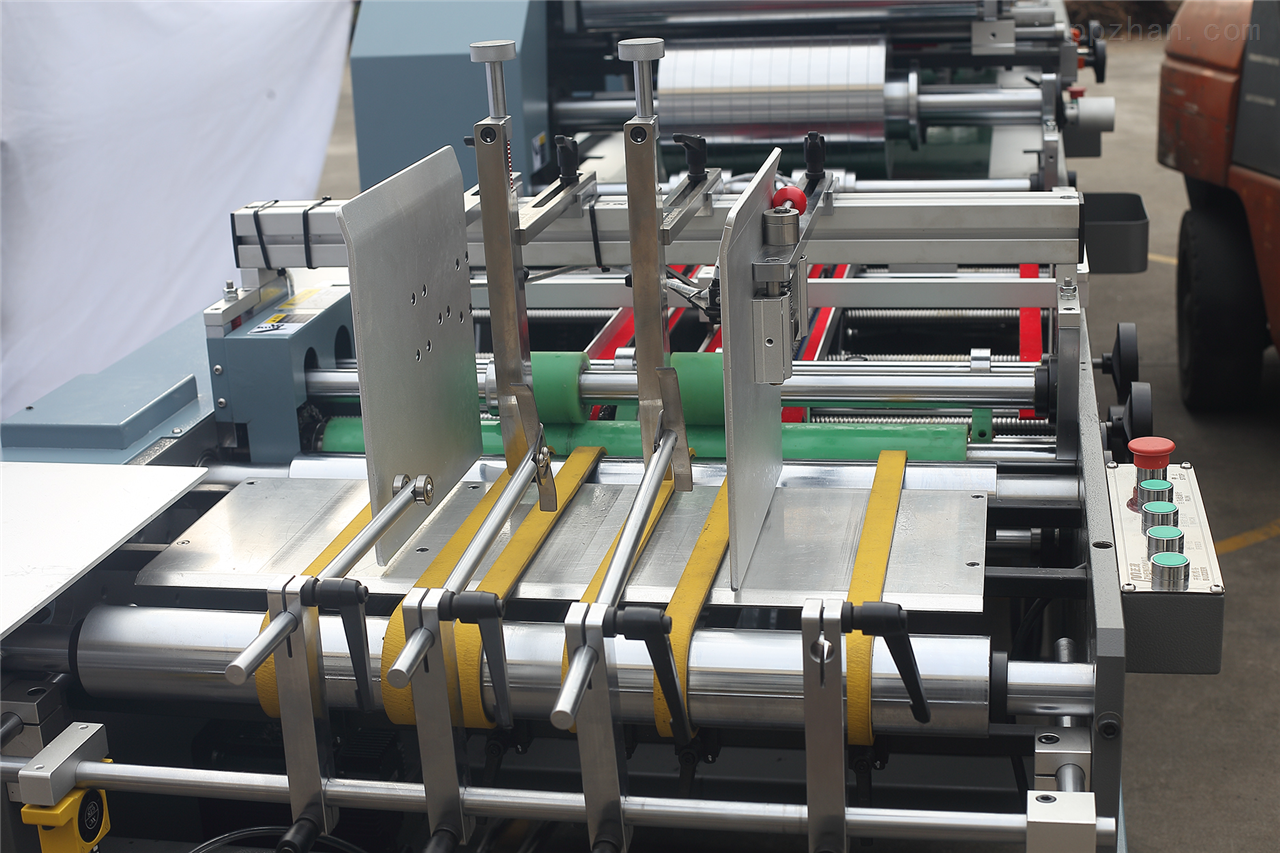

1). Feeding unit:

Independent servo system is adopted for intermittent belt conveying. Intermittent conveying distance can be adjusted as per paper size. Paper extracting belt extracts the paper at the bottom and gets rids of traditional clutch mode to realize continuous paper adding without shutdown. Multiple conveyor belts are equipped with gears and rack units which can quickly adjust the left and right positions of the belt.

2). Gluing unit:

Single high-hardness stainless steel tube rollers transmit the glue. The tube rollers are equipped with a sliding block which can quickly regulate glue thickness. Flexible template gluing is adopted, and the template shop can be engraved according to product requirements. The roller for template installation is graved with a base line, and the template installation is accurate, convenient and quick. Left and right position for gluing can be adjusted freely. Front and back position are adjusted with an adjusted which can adjust front, back, left and right position for gluing without shutdown. When being cleaned and maintained, the glue device can be pulled out. It can be cleaned and maintained more conveniently.

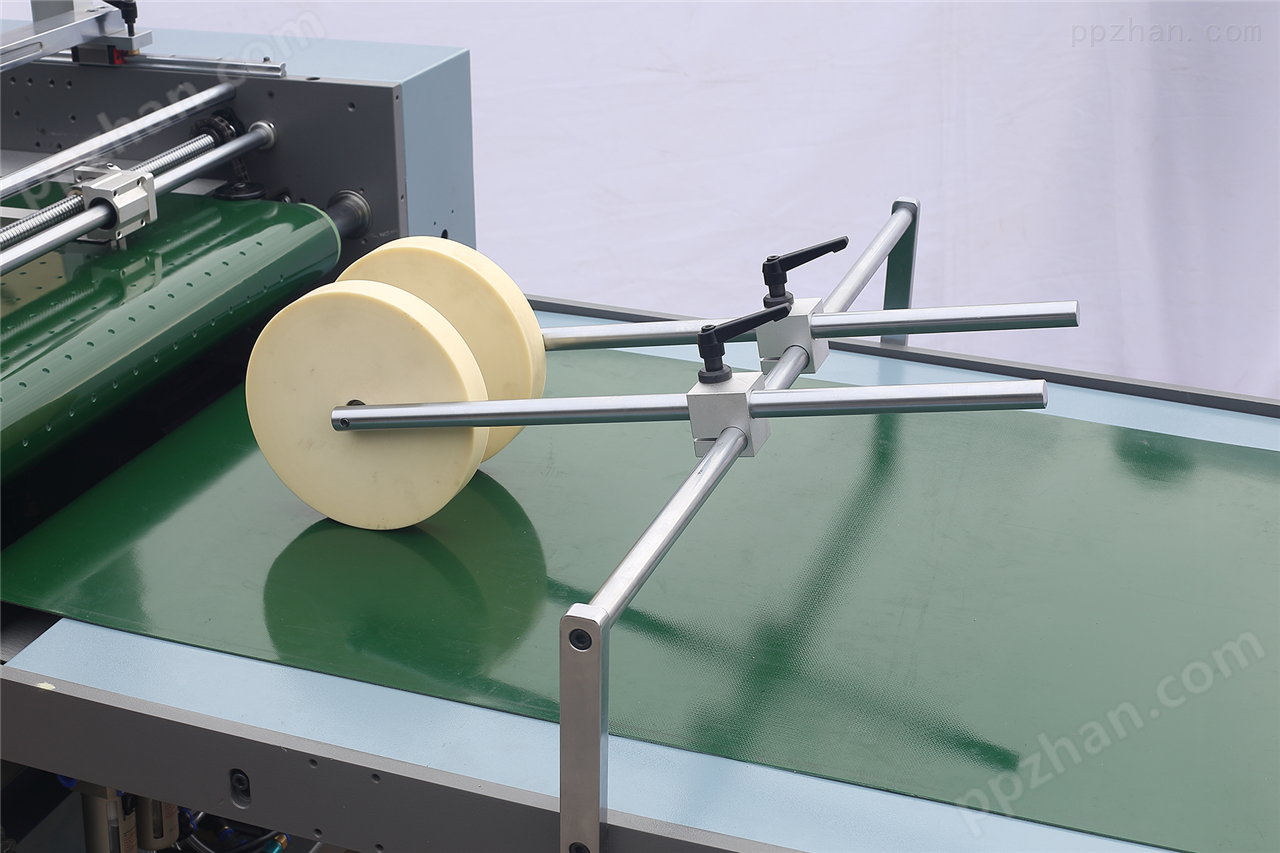

3). Window patching unit:

Independent servo system is adopted. Users can adjust the film length as per product size without shutdown. Meanwhile, chamfer lines are cut automatically. After the paper is positioned accurately according to the above regulations, attach the films to paper box and cut the film via automatically transverse cutter. The precision of film attachment is up to ±0.5mm.

4). Delivery unit:

Imported soft belt conveying can prevent product crushing. Paper is collected tidily in a sandwiching structure, which ensures perfect quality.